Company Roots

Steve Brussow began working at August Witt & Sons feed mill during high school. Following military service in WWII, Steve returned to Loyal and went back to working at the mill.

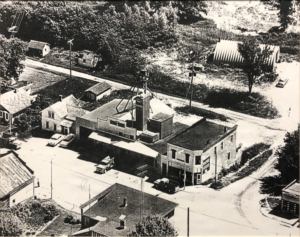

1948

Northside Elevator began when Steve Brussow purchased the existing August Witt & Sons feed mill. Steve raised his family in lodging above the mill on Main Street in Loyal. Space was tight, and the wooden structure was dusty, but the business continued to grow… just like the family. Steve’s son, Tom, worked in the mill as a child and throughout high school before heading to a business college.

1964

Upon graduation from college in 1962, Tom returned to work at the mill in 1964 as a mill operator. During this time, he began taking on more responsibility for the business and its 5 employees. Northside Elevator offered a varied product line and a diversity of services because most farms at this time were multi-species, including dairy cows, chickens, hogs, and horses. Dairy farming was growing and became more of a focus in the region. The Brussows’ commitment to their customers inspired them to seize an opportunity for expanding their business in all directions, enabling them to serve dairies across the entire state.

1968

A fertilizer plant was added to the business and has remained a steady part of growth ever since. This service assisted local farmers in reaching their crops’ fullest potential while giving Northside’s first full-time salesperson more tools for building the business.

1970

It was a cold November evening, the night before deer hunting season opener, when a fire destroyed the mill. A passerby threw a rock through a window, alerting Steve. Luckily, he escaped onto the roof of another structure, before making it safely to the ground. Unfortunately, the mill was a complete loss. However, the fertilizer plant was not damaged, and it became an effective way to stay in touch with farmers. With the mill in ashes, one of Northside Elevator’s best wholesale vendors, OW Trindal, offered to continue servicing Northside Elevator customers at night, after they had serviced their own retail customers. Tom worked with OW Trindal during the day and then serviced Northside Elevator customers by night alongside OW Trindal staff.

1971

Insurance covered losses from the fire and allowed the Brussows to rebuild a mill that was better and more advanced than the original. Shortly after the fire, Steve and Tom bought the land where the current mill is located. A lot of help was offered and shared during the rebuild. Farmers pitched in to help lay block and work alongside the contractor. The new mill was designed with overhead bins and a central scaling system was added, among many other updates. More modern than most for its time, the new Northside Elevator mill helped service farmers more accurately, quickly, and with less intense labor.

1978

The fertilizer division began spraying crops as a convenient service to farm customers.

1982

Steve retires and the business ownership transitions to Tom.

1985

Tim Brussow (Tom’s eldest son) joined the business after graduating from college. Familiarity with the family business came from working at the mill during high school. Upon returning, Tim worked in the shop facility before managing the fertilizer business for the next three years.

Rick Brussow (Tom’s son) joined the family business working in the mill before becoming mill manager in 1996 continuing through 2013.

Northside Elevator constructed its first grain bin (50,000 bushels) to add to the services offered to area growers.

1988

The construction of a pellet mill paved the path for Northside Elevator to quickly become one of the only area suppliers to offer pelleted feed. With this, Northside has more feed delivery, purchasing, and customization options to offer customers.

1990

Northside Elevator internalized trucking/logistics by buying their contractor group, Bixby. By forming NSE Transport, Northside was now able to haul their own feed, internalize costs, and have better control of customer service.

1992

Ted Brussow (Tom’s son) started working in the mill bagging and hauling feed after attending college. Ted performed and participated in almost every job function around the facilities for a couple of years before he spent extended time in the office becoming more familiar with the Northside business.

1998

Ted transitioned Northside into grain contracting and hedging. Since construction in 1985 and in the years following, the grain bins were used for storing grain used in the mill. Ted added Logistics Director, General Manager of Operations, and Risk Advisor for grain contracts to his duties.

2008

Tom retired and business ownership transitioned to Tim, Ted, and Rick. The office space was expanded and redeveloped to meet the needs of the growing staff.

2009

A new feed mill increased manufacturing capacity and is more technologically advanced. Additionally, a new warehouse was constructed.

2013

Jordan Brussow (Tim’s son and 4th generation Brussow family) joined the business, a new grain bin was constructed, and a state-of-the-art fertilizer plant was built. The construction of the new grain bin pushed total grain storage to nearly 3 million bushels. The new fertilizer plant was built, featuring automatic scaling, increasing accuracy and production time. Delivery trucks with variable rate boxes were also added to ensure precision application on the field

2015

A new service shop was built for convenient and timely repair and maintenance of vehicle fleet.

2017

Northside acquired Golden Grain just south of Loyal and has constructed more bins since the acquisition for a total storage capacity of 4.4 million bushels.

2019

A full automation project of the pellet mill was completed for greater efficiency and improved employee safety. Northside constructed a fully independent calf feed mill with stringent biosecurity protocols.

2020

Northside constructed a dry storage facility with 7,000 ton holding capacity, while relocating the rail site and expanding it to a 30-car capacity. Cameron Brussow (Ted’s son and 4th generation Brussow family) joined the family business.

2022

Northside Elevator’s geographic footprint expanded through the purchase of property in Stanley, WI, and began construction on a state-of-the-art fertilizer production facility with advanced logistics. Additionally, Northside acquired Buck Country Grain in Arcadia, WI. With the acquisition of Buck Country Grain comes the highlight of Northside’s expertise in grain and commodity markets and offers another option for procuring locally grown commodities.

Arcadia, WI

2023

The Stanley location is complete, featuring a 40,000 square foot warehouse, an updated fertilizer plant, and a rail spur for receiving bulk commodities and raw materials.

Stanley, WI